'Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Tungsten Carbide Tips(buttons) For Mining, tungsten carbide lift valve, Cemented Carbide Stationary Seal Ring. We insist on honesty and trustworthiness as the foundation of enterprise development, allowing you to buy reliable products at a preferential price and in a fast way. 'High quality products, high quality service' is our advantage and our eternal commitment, in line with the 'service first, the integrity of the world' business philosophy, we continuously progress.

Application:

Carbide snow plow blades are used on the front, underbody, and wing of a snow plow. Carbide snow plow blades look very similar to traditional steel cutting edges; however, they have a carbide insert brazed into the thickness of the steel or overlayed on the face along the bottom of the blade. Carbide is short for Tungsten Carbide; a metal composed of equal parts tungsten and carbon. Carbide is denser than steel enabling it to be a versatile and durable edge material that provides much better wear resistance properties than a cutting edge made of just steel.

Body blade:

1.The blade shall be flat hot -rolled finished steel to meet or exceed specification for A36 or 1020 type steel;

2. Punching shall be 11/16”(or customized) square holes with countersink to receive 5/8”diameter plow bolts.Location and space will be done according to customer’s drawings.

3. The slot for the carbide inserts shall be milled in the center of the blade edge.

Tungsten carbide inserts

1.physical property:The inserts shall be a high shock WC of tungsten carbide with cobalt at least 11%.

Density(g/cm3):14.1-14.6

Hardness(HRA):87.5-89

Transverse Rupture strength(N/mm2):3200 min

Porosity:A06B02C00

2. insert dimension:

Height: .635”+/-.0054(long side)

Width: .365”+/-.010

Length: 1” Nominal

Bottom Angle:25 degrees with a nose radius of 1/16: minimum

Brazing

1. The brazing material shall be a high strength brass.

2. The tungsten carbide inserts shall be positioned in the milled slot at approximately .010 between the inserts the entire length of each cutting edge section

Quality Control

1.All raw materials are tested in terms of density, hardness and TRS before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

Certificates & Quality Control

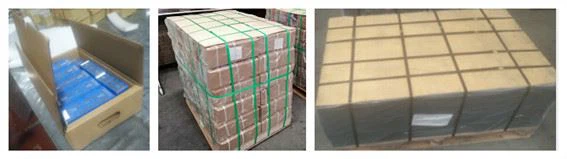

Packing & Shipment

Why choose us?

1.Over many years' history in cemented carbide products research and develop.

2.Up to date production facilities;

3.Complete & strictly QC system throughout the manufacturing process.

4.Lead time as fast as 12-20 days!

To perfect our service, we provide the products with the good quality at the reasonable price for 5D9554 Double Bevel Flat Motor Grader Blade. Technological innovation and technological development have enabled our company to accumulate competitive advantages and thus gain the recognition of our customers. With excellent products and reasonable prices, we are willing to make unremitting efforts for your needs and wholeheartedly cooperate with customers at home and abroad to create brilliant hand in hand.

Hot Tags: snow plow blade, China, suppliers, manufacturers, factory, high quality, hot sale, tungsten carbide flow limitation chamber, Tungsten Carbide Snow Plow Blades, Tumngsten Carbide Thread And Cross Groove Nozzle, Tungsten Carbide Inserts, Cemented Carbide Rotating Seal Ring, tungsten carbide lift valve