We can easily present you with almost every style of merchandise linked to our merchandise range for Tungsten Carbide Sleeves/bushings, Oscillating Carbide Blade, Tungsten Carbide Seal Ring. Relying on its good reputation and high-quality services and products, our company has established our leading position in this industry and become a long-term and stable supplier of many excellent enterprises. We recognize that advancing with the times and forging ahead are the main theme of the times and the inevitable requirement for enterprises to become stronger and bigger. In the process of years of practice, development and improvement, our company is gradually forming a mature after-sales service system.

Tungsten carbide sleeve is a regular type and mainly used in oil and gas industry.It’s an important part of electric submersible pump(ESP) with good wear resistance and high hardness.

Main type:Normal cylindrical axle sleeve,cylindrical axle sleeve with slot,axle sleeve with convex stage,axle sleeve with slot and convex stage,non-standard axle sleeve etc.

This straight type is a very popular item and easy to manufacture.So the output is very large in short time.Also the cost is a little bit lower than other item.

The sleeve can withstand prolonged load,with high chemkical stability aLkali,Alcohol,hydrocarbons acid,oil,detergent,water.

Application

The cemented carbide sleeve will be used mainly for rotating support aligning,anti-thrust and seal of the axle of motor.centrifuge. protector and separator of the submerged electric pump in the adverse working conditions of high speed rotation. sand lash abrasion and gas corrosion in the oil field,such as slide bearing sleeve.motor axle sleeve. aligning bearing sleeve,anti-thrust bearing sleeve and seal axle sleeve.

Features

1.Material:100% virgin raw material.

2.Grade:Various grades for choice.

3.Advanced production equipment and testing equipment.

4.Precision Ground and polished.

5.High wear resistance,high hardness and impact toughness.

6.Advanced technology , automatic pressing,HIP sintering and precision grinding.

All abrasion resistance carbide wear parts are made by WC and Cobalt or Nickel , which is excellent in wear resistance;

Certificates & Quality Control

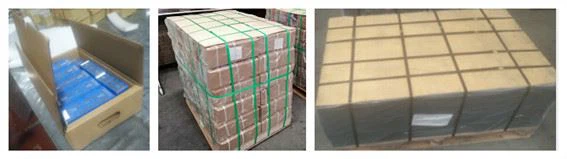

Packing & Shipment

Most parts are packed in carton inner plastic containers.Also we pack some cartons on man-made wooden pallet for ocean or airway.Except above,we shall pack parts as customized.We usually stamp our box labels to end user and stamp trader’s box label on the packages.

We have achieved the development goals of standardization of business, scientific management, humanization of service and informationization of process in the Durable Wear Bespoke Tungsten Carbide Components Straight Bushings industry. We implement real-time recycling of leftover materials and defective products, greatly improving economic benefits. It needs the close cooperation of market and technology, and the collaborative innovation of several departments to create differentiated value.

Hot Tags: tungsten carbide straight sleeve, China, suppliers, manufacturers, factory, high quality, hot sale, Tungsten Carbide Coal Mining Tips, Tungsten Carbide Milling Inserts, Tungsten Carbide Snow Plow Blades, tungsten carbide drilling tips, Tungsten Carbide Drilling Tips For Oil, grader blades